Stockade staples deliver superior durability on the fence line. This is no accident. It is how they were designed.

Stockade’s investment into creating a truly superior staple runs in tandem with its premium cordless tool development and forms part of a total system to deliver superior, consistent results on the fence line.

North Island territory manager and former contractor Mike Billinghurst says there is no comparison.”Hammer-driven staples and power-driven staples are not the same. Stockade power-driven staples will not chip and go in straighter than hammering. They don’t need adjusting, they hold strong and won’t pull out.”

“Above all else, Stockade staples, designed by New Zealand engineers, are strong, durable, and long-lasting.”

Graeme Young is one of the engineers who was at the forefront of developing Stockade’s 3.15mm batten staples more than two decades ago.

“We wanted to help farmers and contractors tackle battening. Every step of the way, we listened to farmers and fencing contractors to develop a state-of-the-art stapler tool and make our staples even better. We talked extensively to farmers and contractors about staples. Issues with chipping, rusting out, holding power. Then we set out to find ways to improve the performance of the staple. It started from there.”

The Stockade challenge was to create a staple that met the needs of farming, contracting, horticulture, and viticulture systems. Fortunately, New Zealand provided the perfect rugged testing ground to develop this superior staple: a staple that would hold firm for the lifetime of the fence, both from corrosion and a withdrawal standpoint, a staple that could tolerate temperature extremes, animal movement, and heavy crop loads.

Creating this perfect staple was a considered and rigorous process. Clever engineering.

“We designed and trialed a number of iterations over years: different coatings and leg designs. Ultimately, we were in pursuit of increased durability. Every farmer would expect their fence to stand up for at least 30 years, so should their staple.”

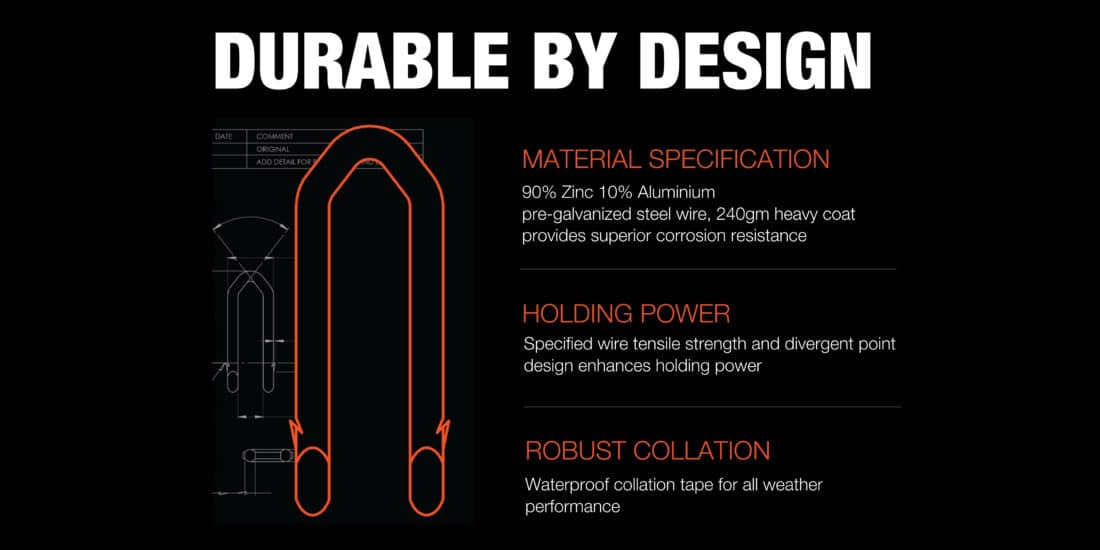

To deliver this, Stockade created a heavier coat containing 90% zinc and 10% aluminum providing superior corrosion resistance over standard hot-dipped galvanized staples — and a stronger, longer hold in battens.

In New Zealand, most new fences are built using a medium thickness galvanized wire coating with a standard Zinc or Zinc: Aluminum coating. All in all, this means many staples on the market start to rust well before the life of fence wires. Not Stockade staples. Stockade staples have six times the corrosion protection compared to standard zinc galvanizing – out-performing other staples in the market.

Graeme says Stockade has always wanted to be the best in class. “We wanted to make sure our staple has the right coating, right tensile strength, right depth of drive, no damage to the staple crown when it is driven in, specially-shaped driver blades. All those things need to be correct.”

“Everything we learned in developing the most durable batten staple, we have applied to the Stockade 4mm post staples, offering a superior post and batten stapling system.”

Not all staples are created equal and there are no long-term savings from using inferior-quality staples. So, when you want a staple to hold the strain and last the distance, look for the consistent quality, strength, and engineered ingenuity of Stockade staples.

Contact your local Stockade representative for a demonstration of the ST400i or ST315i and our superior long-lasting durable staples to learn how you can improve your business productivity.